Zhuo Wen Wu '11

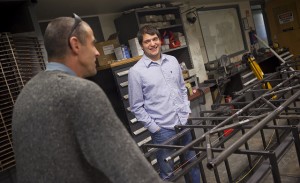

Alec Bernstein ’11 (Colts Neck, N.J.) walks into a lab in Acopian Engineering Center and chats with his classmates about the progress of their class assignment. The members of Lafayette’s steel bridge team are hard at work designing and fabricating a bridge for this year’s national competition.

“Many students on the steel bridge team frequently spend upwards of 50 hours in the lab each week working on the bridge. Even though it is one of the most time-intensive classes at Lafayette, it is definitely one of the most rewarding,” explains the civil engineering major.

Diane Tran ’11

Diane Tran ’11 (West Hartford, Conn.) agrees with Bernstein. “This experience is unique. Most other schools do not have a steel bridge team, and even fewer have a steel bridge competition incorporated into their curriculum. Not only have I learned about structures and steel design by participating, but I have also gained time-management skills, team-building skills, and machine shop skills, and I have learned the importance of precision and accuracy.”

This year’s team is also made up of civil engineering majors Brian Carey ’11 (Seaford, Del.), Ryan Flaherty ’11 (Croton On Hudson, N.Y.), Blake Rhood ’11 (New London Township, Pa.), Emily Simon ’11 (Green Village, N.J.), and Zhou Wen “Zeus” Wu ’11 (New York, N.Y.), and mechanical engineering major Martin Racenis ’11 (Hopkinton, Mass.). The group’s adviser is Stephen Kurtz, associate professor of civil and environmental engineering, who teaches the course as an independent study.

Alec Bernstein ’11 speaks with Professor Stephen Kurtz.

They will compete in the Mid-Atlantic regional conference April 15-17 at Drexel University with the hopes of qualifying for the National Student Steel Bridge Competition May 20-21 at Texas A&M University. Lafayette has made the national tournament five of the last six years and placed seventh in the nation for the last two years.

The team’s task is to design and fabricate a bridge that will support a randomly patterned 2,500 lb. load over a span of approximately 21 feet. The bridge is fabricated in sections and is assembled during timed construction during the competition. Teams are judged on their construction speed, bridge weight, stiffness, lateral integrity, and aesthetics.

Ryan Flaherty ’11

Bernstein explains, “Everyone on the team is taking the designs that were finalized at the beginning of this semester and moving them from a computer screen to steel. There are many tasks that go into this project during fabrication, and each person has a role.”

Even though there are individual tasks, each student has to work together to make sure the correct dimensions and the same procedure for fabrication are followed.

“Since we are applying what we learned in class to a hands-on project, you see things in a different light. It’s more like how the real world is,” says Tran. “This is especially helpful for me because I plan to get a job at a civil engineering firm to gain some professional experience before going to graduate school. Steel bridge has taught me a lot that I can take away with me.”

Emily Simon '11 and Professor Stephen Kurtz

As a Fulbright Scholar finalist, after graduation Bernstein is hoping to travel to the Netherlands to do a year of research in water resources engineering. Otherwise, he is planning to attend graduate school for water resources engineering and hydrology next year.

“I joined this class to work with others on a team for a real-life project,” he says. “I wanted to pursue something this semester that has more implications on life than just a grade. As a civil engineer at Lafayette, you are exposed to so many different [areas] of engineering that help you decide what you want to do with your life.”