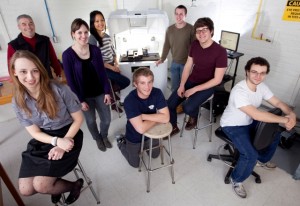

Members of the metal prototype machine team are, from left, Elizabeth Parisi ’12; Tom Defazio, lab coordinator for chemical and civil engineering; Lauren Marzocca ’12; Ngan "Kate" Vu ’12; Evan Goldberg ’12; Ricky Schwalje ’12; Colin Rementer ’12; and Bill Binder ’12.

A material additive manufacturing suite in Acopian is providing opportunities for students and faculty to make contributions to interdisciplinary engineering design in all of Lafayette’s engineering areas, as well as projects being done in departments across campus.

“This equipment is a vehicle for the integration of liberal arts and engineering,” says James Ferri, associate professor and head of chemical and biomolecular engineering. “We would like this technology to signify a ‘green light, signaling we are open to cross-divisional collaboration at the College. We are trying to send a message that we want to work with our colleagues on campus.”

The College’s new integrated metal prototype machine allows students to efficiently manufacture components out of metal, polymer, and ceramic. Using computer technology along with a process involving printing by alternating between layers of a binder and metal powder, curing in ovens, and sintering, the machine creates parts in approximately 12 hours, depending on their size.

“Integrated metal prototyping machines are an extremely important technology because of their ability to rapidly produce a finished product,” explains Colin Rementer ’12, a chemical engineering major. “Fabricating a metal prototype by creating and then casting a mold could take much longer, and likely could not be done onsite.”

Rementer has been working with the machine in an interdisciplinary team mentored by Ferri, and it has now been incorporated into the chemical and biomolecular engineering senior design course Integrated Chemical Engineering and Design Synthesis. Other team members include chemical engineering majors Elizabeth Parisi ’12 (Pittsburgh, Pa.), Lauren Marzocca ’12 (Lakewood, N.J.), Ngan Vu ’12 (Astoria, N.Y.), Evan Goldberg ’12 (Avon, Conn.), Ricky Schwalje ’12 (Hillsborough, N.J.); mechanical engineering major Bill Binder ’12 (Huntington, N.Y.); and Tom Defazio, lab coordinator for chemical and civil engineering.

Ferri says there are multiple ways to integrate this manufacturing method into the curriculum.

“Students are already making custom parts for other research projects,” he says. “As part of the senior design project, students are working with the company which has developed this technology, ExOne, to optimize the system. Chemical and mechanical engineers are working specifically with the reactive glues, seeking to decrease defects during manufacture.” ExOne is owned by Lafayette Trustee Kent Rockwell ’66.

Since there are artists who use digital media, realization of their creations through materials additive manufacturing is a natural extension of their work. Ferri and the chemical and biomolecular engineering department have already begun conversations with visual arts professors to see how they can work together.

“This project has helped bring together underclassmen and upperclassmen and has bridged departments,” says Ferri. “Upperclassmen can train first-year students and younger engineers on what the work is all about. It also gives them important hands-on experience in leadership and management.”

For Rementer, this experience has helped grow his understanding of the chemical engineering field and possibilities.

“Working on this project has allowed me to experience the application of much of the technical knowledge I learned throughout my studies at Lafayette,” he says. “This project has been invaluable to the development of my skills as a researcher and an engineer. It has also made me realize that there are many applications of chemical engineering that I am not aware of, and I have felt encouraged to explore them.”