By Stephen Wilson

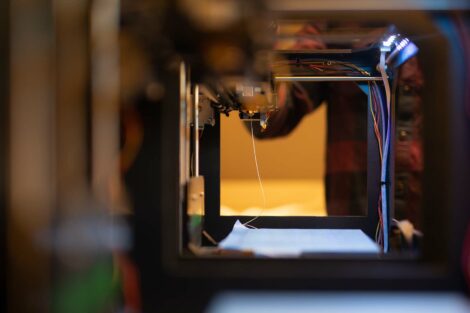

A 3D printer spools hot plastic filament to shape a tiny heart. When completed, it will be cast in silicone. That mold will then be filled with local Belgian chocolate.

Making never tasted so good.

It’s just one idea for engaging programming designed to attract students to a newly opened maker space in Dyer Center for Innovation and Entrepreneurship.

If that idea is too sweet, then how about drone building or designing an electric skateboard?

Both are on deck.

Behind these ideas are several Dyer fellows and enthusiasts. Meet George Crittenden ’21, who saw the room when Rockwell Integrated Sciences Center opened and thought it would be a perfect place to engage students who have or want to develop “an entrepreneurial edge.”

“For students like me who are not an engineering major, you can have a hard time finding a maker space without being put on a wait list,” he says.

So he, Sebastian Wallach ’23, and Jenny Chen ’22 set to work. They combined their own experience with labs and on teams, like robotics and CO2 racers, and met with folks like Scott Hummel, William Jeffers Director of the Engineering Division, and Jonathan Macasevich, technology specialist at Skillman Library, and also visited spaces, both in person and virtually.

“Northampton Community College’s Fab Lab has 8,000 square feet of space,” says Wallach.

“Along with every imaginable tool,” says Chen.

“And full-time technicians and woodworkers,” says Crittenden.

Of course, there was no need to recreate something so comprehensive, but it did inspire them to look beyond their space constraints and focus more on what was possible.

The team shaped a proposal of equipment, programming, and approaches and presented it to Dyer staff.

The students wanted to start small and build based on need. Small meant 3D printing, hand tools, and soldering system.

“Having technology is important,” says Wallach. “But going back to basics so we can screw pieces together is crucial to prototyping.”

Wallach made a call to his father, Cliff, who operates a 3D printing company, in hopes he might donate some supplies, which he happily did.

Once off the ground, Crittenden stepped into other Dyer projects and let Wallach and Chen take the lead.

At the kickoff event, a group of students listen as Wallach walks through some basics—the space, tools, printers, and programs to get started. All students can obtain a fob and gain access to the space.

“We want this space to be available to all students and hope that we have what they need to get their imaginations working or bring what they’ve imagined to life,” says Wallach.

Chen also sees the opportunity for student-makers to form tinker teams, develop workshop leaders, and offer big and small project builds.

“If you have an idea and want to turn it into a product, we have the tools and team to help,” she says.

And they have plans to grow, adding a laser cutter and more hand tools. But they are waiting for student surveys to help make decisions.

So watch for announcements to sew your own backpack or craft a fabric folding chair or make an April Fools’ gag.

“Our goal is to design the space as we go, adding tools and programs based on what students want,” Chen says. “And to get people here from across campus who are ready to make.”