Mechanical engineering faculty designed and shipped portable lab equipment to homebound students

By Bryan Hay

Determined to provide a fulfilling experience for remote learning students in a popular control systems course, a trio of resourceful mechanical engineering faculty redesigned and shipped lab equipment directly to students.

Mechanical engineering professors Dan Sabatino, Jeff Helm, and Alex Brown teamed up right after the spring semester ended to miniaturize equipment used to help teach problem-solving techniques in ME480: Control Systems and Mechatronics.

Together they designed a portable version of the lab “rig” used in the course, and built and shipped 70 units to students in time for the fall semester.

ME480 provides a study of the basic principles and modes of operation of automatic control systems and familiarizes students with the concepts and design of feedback control systems.

“Our students are all able to get the hands-on experience that ME480 has a reputation for, and they can experience the rigors of the course in the comfort of their own homes,” Brown says. “This required a redesign of many of the lab exercises and some creative approaches to troubleshooting during lab periods, but it has worked well so far.

“We were working on this pretty much nonstop since May 15, and were just barely able to get them all designed, built, tested, and shipped before the start of the fall semester,” he says.

“Although the circumstances dictated a shift toward these personalized workstations, there have been benefits that will make their way into future offerings of the course after we return to campus,” says Sabatino, who heads the mechanical engineering department.

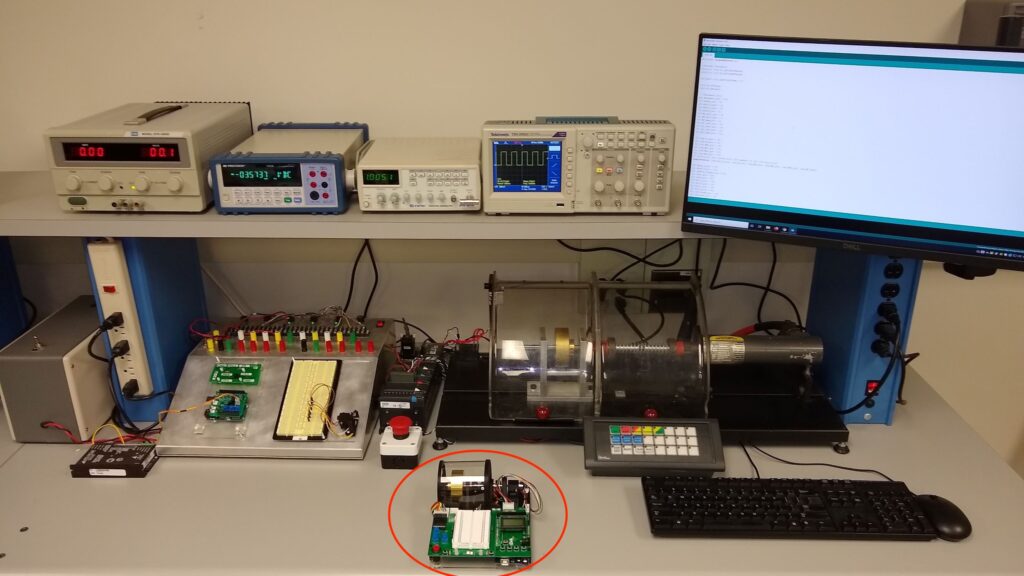

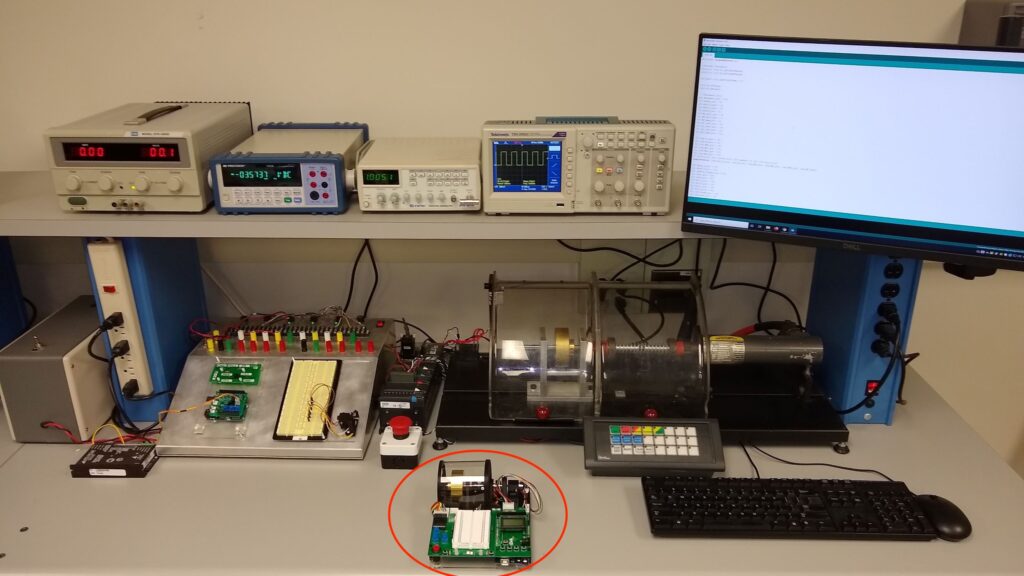

The old ME480 lab station setup, with the smaller new rig placed in front.

“The portable stations make working on the projects more accessible (where equipment access was limited in the past) and allows students to both collaborate on teams while still having direct experience,” he adds. “The kits were designed to be modular so they can provide a variety of experiences. They have already found use in another course, ES201 (a lecture and lab-based course).

In order to perform experiments with the motor, the students had to use the buttons and screen on the rig to develop a redundant safety system and user interface, as if the system were a machine in a factory.

“Later in the semester, the students will implement closed loop feedback control on the position and velocity of the brass inertia that is attached to the motor system, both with and without a torsionally flexible shaft,” Brown says.

In ES201, students are using the same machine for totally different experiments.

“For instance, they have already used it to develop a detailed dynamic mathematical model for a Fender Stratocaster guitar pickup,” Brown says. “The ES201 students are also using the rig to learn to build circuits, take measurements from sensors that are commonly used across engineering disciplines, and learn about measurement error and statistics.

“Remote learning has its challenges, but we’re doing our best to deliver an equally effective learning experience for our homebound students,” Brown says.