A summer internship is introducing chemical engineering major Becky Geisler ’03 (Sinking Spring, Pa.) to the powder coating process.

Geisler is a summer intern at the Morton Powder Coatings Research and Development Facility in Flying Hills, Pa. The operation is a division of Rohm & Haas Chemical Corporation. Geisler is working on several long-term projects and is responsible for assisting her supervisor with any emergency situations and projects that arise.

Her work is in the area of powder coatings, a technology in which both metal and wood materials — such as filing cabinets, desks, hubcaps, and machinery – are covered to simulate the appearance of a paint finish. To accomplish this, a polymer-based powder mixture is created, extruded (heated to a temperature just above its glass transition temperature to soften and mix the materials), rolled into flat sheets, and chipped and ground to a fine powder. The powder is sprayed on the metal or wood part, and then baked to cure (harden) the powder coating. When cool, the coating is smooth and similar to a paint finish.

Geisler’s daily tasks include the powder coating process, assessing the durability and other properties of the coating, and adjusting variables to obtain a particular color, glossiness, or other desired property. In another project, she is studying how the shape and/or size of the powder particles affect the coating and its properties.

“My work is assigned to me by my supervisor, but much of my work is done independently,” she says. “I have also had the opportunity to write and distribute a memo detailing my work on one particular project. I feel that this was an important experience because future situations may arise where I will be responsible for presenting researched data in an organized manner.”

Powder coating technology involves polymer, inorganic, and organic chemistry, all of which are part of Lafayette’s chemical engineering curriculum.

“My work as an intern does not take into account much chemistry, but hopefully as I learn more about the powder coating process and better understand it, I will be able to be more involved in chemistry/chemical engineering-related research,” says Geisler. “There is a degree of engineering involved, as much of my work is trial-and-error and involves many variables. For the most part, my job is unlike anything I have ever done in the classroom, and much of what I know about powder coatings I learned through my internship.”

The work has done more than simply familiarize Geisler with powder coating technology. “In many ways, I have come to make connections between the chemistry I learned in the classroom and how it affects the properties of powder coatings,” she says. “Although I am not sure what area of chemical engineering I will pursue after graduation, I have enjoyed learning about polymers and would probably enjoy concentrating on polymer-related research/development. Powder coatings is one application of polymer chemistry, and although I have not been able to delve into much of the polymer chemistry behind the powders, I have been able to gain experience in a polymer-related field.”

Geisler enjoys the degree of independence that Morton is allowing her on the job. “Most of research and development is done independently alongside other employees who are working on their own projects,” she explains. “I enjoy that I can work alone, but that I am able to enjoy the company of others at the same time. The atmosphere is relatively relaxed, while at the same time the employees are conscious of their goals and deadlines. The other employees and interns have been very friendly, and I have enjoyed getting to know them and learning from their experience in polymer coatings. I have also been impressed by the degree of respect that my supervisor and fellow employees have for me and my work.”

The internship began May 21 and will conclude the week of Aug. 20.

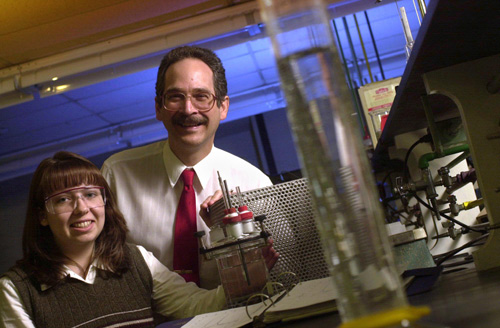

In an EXCEL Scholars project, Rebecca Geisler ’03, a chemical engineering major, analyzes the dynamics of stainless steel corrosion with Ricardo Bogaert-Alvarez, assistant professor of chemical engineering.

1 Comment

Comments are closed.