Lafayette chemical engineering major Daniel Connolly won first prize for his research presentation at the mid-Atlantic regional conference of the American Institute of Chemical Engineers March 16-17 at Virginia Polytechnic Institute.

Connolly, a senior Marquis Scholar from Meadville, Pa., will receive a cash prize and present his work again at the institute’s national meeting in November in Indianapolis, Ind. He took top honors among 28 entrants from mid-Atlantic colleges and universities who participated in the student research competition at Virginia Tech.

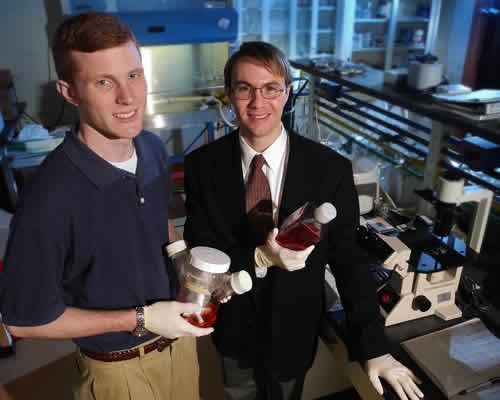

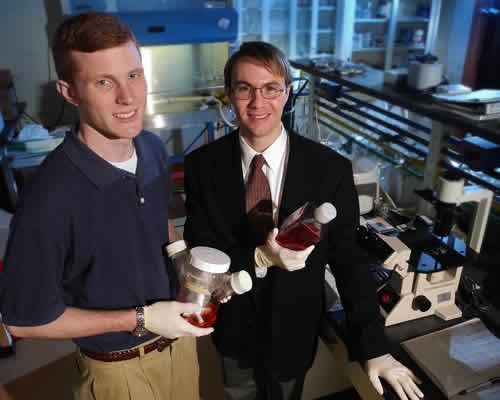

Connolly’s presentation was on “Calibration of Process Shear Conditions Using Shear Marker Fluids: Hybridoma Cell Death as an Indicator of Hydrodynamic Shear,” the topic of a senior thesis he is currently writing to qualify for departmental honors when he receives his Lafayette diploma May 25. His adviser is James K. Ferri, assistant professor of chemical engineering.

Connolly’s work could help the chemical industry bolster the quality of fluids shipped through pipelines. The research involves identifying a fluid that can be used to calibrate the forces applied on substances by complex pipelines.

Connolly says he picked this topic because he wanted to perform research that could be directly applied in industry.

“I feel this project has a practical use once it is completed, and that means a lot to me,” he says. He developed the thesis from work he did last summer as a process engineering intern with the Chemicals Product Support Team (Chem PST) at Air Products & Chemicals Inc., Allentown, Pa.

When a company pumps a fluid through a pipeline, Connolly explains, the force of the substance hitting the walls distorts its properties, such as viscosity or thickness, and shear force tends to decrease its quality.

“For a more detailed piping network, it is difficult to model the magnitude of the forces imparted on a particular product,” says Connolly. “Therefore, within my research, I am looking to investigate a fluid that will degrade in a physical property under controlled shear conditions and within a simple geometry such as a capillary tube.

“By calibrating these forces, the industry is better able to design the processes to prevent loss of product quality,” he adds.

Connolly is conducting his research in collaboration with engineers at Air Products, where he worked on an operability hazard review (OPHR) for an emulsions plant in Los Angeles last summer. Plants carry out this review every five years, seeking ways to improve safety.

“With a hazard review comes many action items that are designated for the plant, as well as research and development, and my group, Chem PST, to carry out,” Connolly explains. “My role was to finish the OPHR action items for the City of Industry plant in Los Angeles. With this opportunity, I was able to apply some of the skills that I have learned in the classroom.”

He learned of the internship opportunity at Air Products from Javad Tavakoli, associate professor and head of chemical engineering, then applied through Lafayette Career Services, whose Gateway program matches students with a professional career adviser and provides access to alumni who give practical advice about careers in their fields, among other services.

Two summers ago, Connolly worked with emulsions manufacturing at Air Products Polymers Group in Piedmont, S.C. “The plant experience allowed me to get a hands-on experience that you don’t get in an office or classroom,” he says. “I was able to start to apply what I learned in the classroom.”

Connolly also enjoys working with Ferri on research and in the classroom.

“He has always taken the time to go through a derivation or a concept and explain it when I’m not understanding it completely,” he says. “I have also had Dr. Ferri for two classes here at Lafayette — both great experiences where I’ve learned a lot and have been able to apply what I’ve learned in industry during my internships. I feel that Dr. Ferri is a valuable asset to the chemical engineering faculty.”

Connolly believes Lafayette provides “a good environment for extensive and independent research mainly due to its faculty/student ratio. With the small numbers, students are able to learn who their professors really are and that’s not something you get from just going to a lecture.” He believes student-faculty interaction at Lafayette fosters more learning.

In 1999 Connolly won second place for his paper on the use of sunlight to disinfect contaminated water at the national conference of the American Institute of Chemical Engineers in Dallas, Tex. As an EXCEL Scholar, he worked with Tavakoli to develop an inexpensive and simple way for people in undeveloped regions to disinfect water by using sunlight. A prototype unit, named Solar Biocide, was tested in Peru after successful experiments at Lafayette.

“I have a real interest in environmental science, and when I approached Professor Tavakoli as a freshman, I was surprised that as an undergraduate I could be part of such serious research,” Connolly said. “We worked together on something that could really change people’s lives.”

Connolly was invited to join Phi Beta Kappa, the oldest and most respected undergraduate honors organization in the United States, as a junior last spring. He also has received the Eugene P. Chase Phi Beta Kappa Prize, given to sophomores who have demonstrated scholarship as first-year students.

Connolly is a member of Tau Beta Pi (national engineering honorary society), the American Institute of Chemical Engineers, Lafayette Organization of Science and Technology, Lafayette Environmental Awareness and Protection, and Lafayette Christian Fellowship. He also does community service through Lafayette’s Landis Community Outreach Center.

A National Leader in Undergraduate Research. Daniel Connolly ’02 won second place for his presentation of research with James Ferri, assistant professor of chemical engineering, at the American Institute of Chemical Engineers’ annual meeting.