Richard Koplin ’64, clinical associate professor at New York Eye and Ear Infirmary, spent a year seeking someone to help complete research he began with his deceased business partner, going as far as Paris to no avail. Then he had an epiphany – why not tap into his alma mater’s strong engineering reputation?

Koplin, who also runs a small technology company, develops devices specifically for the field of ophthalmology such as measuring devices for Lasik surgery. When his partner passed away, it left a void of engineering know-how at the firm.

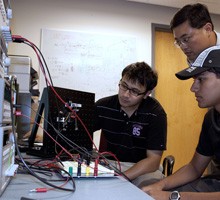

That’s where Yih-Choung Yu, associate professor of electrical and computer engineering, and electrical and computer engineering majors Ahsan Nawroj ’12 (Dhaka, Bangladesh) and Shailesh Shrestha ’11 (Pokhara, Nepal) enter the equation. They are picking up where Koplin’s partner left off, coming up with a unique and efficient product.

According to Koplin, the technology used to diagnose eye diseases is similar to the ultrasound used to view a fetus. This technology is particularly important when a doctor cannot see directly into a patient’s eye due to an obstruction like cataracts or blood. The Lafayette team’s challenge is to improve the front end of the diagnostic probe, an ultrasonic device that projects sound into the eye. Through software, the reflected echoes are manipulated into a representative two- or three-dimensional image of the eye.

“For the students, this is an introduction to the challenges of the entrepreneurial world – with all the risks made abundantly clear, as well as potential rewards, for this type of effort,” says Koplin, who has been working on the project for a year-and-a-half and has a one-year agreement with the College. “By challenging the students to view the ‘problem’ as representative of what we live with in a real business environment, we intend to encourage them to think like inventors. We want them to consider this their baby. We want them to be aggressive and take risks.”

Koplin and his chief technologist, who is overseeing the project with Yu, have brought the group to a manufacturing company in Long Island, N.Y., and visit the campus regularly to offer lectures and review their work.

“In industry, a project involved with real-world applications usually requires the knowledge and communication skills across multiple disciplines, the awareness of intellectual property, the ability in project management, and the understanding of the importance of cost-effectiveness in product development,” says Yu. “It is extremely difficult to include all of these issues in an academic project due to the limitations on time and resources. This project provides undergraduate students the opportunity to understand the scale of a real-world project and to apply their engineering skills in product design with multiple aspects and constraints.”

For Nawroj, the entire process has been an incredible learning experience. He is designing software to run the device and testing the mechanical properties of the larger prototype to match the features of the actual probe to be industrially developed. Gaining a glimpse into how industry functions and working within budget constraints have been the most beneficial aspects of the project.

“I’m learning a lot about the way things work outside the classroom,” says Nawroj, who plans to attend graduate school after Lafayette. “A world where everything has costs that one is directly accountable for increases the challenge of work. The fact is that a lot of concepts cannot be taught in any single course; one must learn them simply by doing. Everything I have learned in class suddenly feels like the tip of a very big iceberg.”

Working with Koplin has even given him a jumpstart on materials he hasn’t been exposed to yet. For instance, he has been working on circuits that he’ll learn about next year.

“Mr. Koplin is a tremendous help to the prototype design, and I have been learning from him the value of innovation,” he says. “It is certainly exciting to work with an alumnus, and I feel very fortunate to work closely with a person who clearly is motivated and very intelligent.”

Koplin adds that not only is this a one-of-a-kind experience for the student team, but for the College as well. He hopes it will open similar research avenues for future undergraduates.

“This idea would only happen at a college like Lafayette, where the school provides great latitude and really encourages and embraces individual and novel efforts from both their undergraduates and alumni,” he says.

2 Comments

Comments are closed.