Almost every day during the January interim session between semesters, Marquis Scholar Rebecca Geisler (Sinking Spring, Pa.), a junior chemical engineering major, spent hours staring at stainless steel and causing it to corrode.

Working as an EXCEL Scholar with Ricardo Bogaert-Alvarez, assistant professor of chemical engineering, Geisler was trying to learn whether polished steel would develop surface pits more slowly, and whether high concentrations of salt would pit more quickly.

“Pitting corrosion occurs naturally in a corrosive environment containing chlorides, usually over the course of several years,” Geisler says, explaining that she and Bogaert-Alvarez “drastically accelerated” the process, making it occur in two to four hours by using an electrochemical technique called cyclic polarization.

During most of her experiments, Geisler filled a “corrosion cell” with a solution containing salt, then added a sample of steel called the “working electrode,” a sample of graphite or other metal called the “counter electrode” and a “reference electrode.” After that, she electrified the samples to cause corrosion to happen more quickly.

“Like most research projects, the data collection process is somewhat slow and time-consuming,” Geisler says, explaining that each experimental run lasted at least five hours. “However, I am excited to look at our final data and draw conclusions about the impact of our variables on pitting corrosion of the samples. To date, there are no documented studies that quantitatively correlate cyclic polarization with polishing and salt solution concentration.”

Geisler spent about 35 hours a week on the research during the January interim session and plans to spend about eight hours a week in the lab during the spring semester.

“Rebecca is a very independent and resourceful student,” Bogaert-Alvarez says. “She also arranged the schedule of the experiments and she’s going to work closely with me on the analysis of the results. I’m very proud of her work.”

Geisler also conducted EXCEL research during the January 2001 interim session, assisting William Miles, associate professor of chemistry, with synthesizing cholic acid derivatives.

“I really appreciate the professors here at Lafayette, especially in the chemical engineering department,” she says. “They are genuinely concerned with whether the students comprehend and can apply class material, and they make themselves very available for help outside of the classroom. Many of them also make an effort to become personally acquainted with the students, which makes the professors more approachable and office-hours visits more productive.”

Geisler, who plans to work as a chemical engineer after she graduates from Lafayette, says she is most interested in research and development and hopes to take graduate courses while working.

A graduate of Wilson High School, Geisler completed a summer internship at the Morton Powder Coatings Research and Development Facility in Flying Hills, Pa., last summer. Her work was in the area of powder coatings, a technology in which both metal and wood materials — such as filing cabinets, desks, hubcaps, and machinery – are covered to simulate the appearance of a paint finish.

Geisler is a member of the campus chapter of Tau Beta Pi, the national engineering honor society. She also is treasurer of Lafayette Christian Fellowship and helps plan weekly small-group Bible studies and meetings for the group.

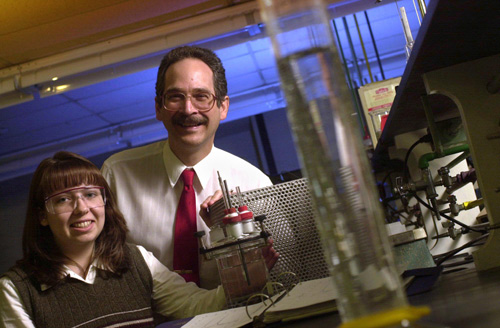

In an EXCEL Scholars project, Rebecca Geisler ’03, a chemical engineering major, analyzes the dynamics of stainless steel corrosion with Ricardo Bogaert-Alvarez, assistant professor of chemical engineering.