Michelle Mendoza ’11 was drawn to chemical engineering because of a “desire to do something more than be just a scientist. I was attracted to how chemical engineers use chemistry to create products that enrich the day-to-day lives of the consumer.”

This past year, Mendoza, who graduated in May, got hands-on experience with product creation during the two-semester senior capstone design sequence for chemical engineering majors. The course groups students together in design teams to tackle several projects that could easily be work they would encounter on their first jobs.

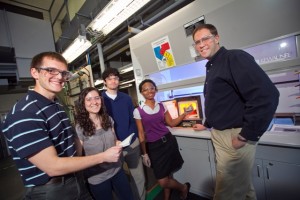

Professor James Ferri, pointing, guides the student team working on the microfueler project.

Mendoza, who will be working at the Air Products and Chemicals plant in New Orleans through its career development program, says her project was key to getting her first position.

“[It] provided me with the best possible opportunity to apply the skills I learned before needing to apply them in my job after graduation. This project also helped to build my confidence in presenting my ideas and thoughts to a supervisor.”

The two-course design sequence is team taught by Joshua Levinson, assistant professor of chemical and biomolecular engineering, and James Ferri, associate professor and head of chemical and biomolecular engineering.

Three teams took on projects focusing on designing a conceptual gas-to-liquids manufacturing facility, an industrial collaboration with Rockwood Pigments of Easton, and a microfueler project to create a small-scale ethanol-producing fuel station.

“Such hands-on experience provides an effective platform for the practice of their engineering knowledge while also giving them experience with real-world expectations and business concerns,” says Levinson. “These hands-on projects are piloting where we’d like to bring the capstone experience for all future offerings of this course, and it should not be surprising that most students (along with the department) value such hands-on experience.”

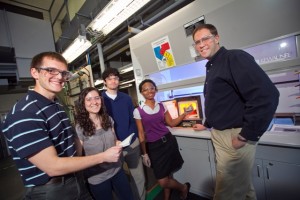

Glen Tennyson '11, Lauren Huyett '11, Andrew Lai '11, Zainab Nandawula ’11, and Professor Joshua Levinson worked on the Rockwood Pigments project.

Mendoza was on the design team for the gas-to-liquids plant project. The group studied equipment for the plant and performed cost analyses of what would work best.

“My team worked on a design that would convert natural gas into the liquid fuels: petroleum, naphtha, and diesel,” she says. “The design consisted of a complete material and energy balance over the plant as well as an in-depth economic analysis over the 15-year life of the plant.”

The students, who worked with Rockwood Pigments, a worldwide leader in the production of iron-oxide based pigments, took numerous on-site visits working directly with the staff to understand the process and collect relevant data on the large-scale manufacturing system. The team was made up of Robert Froio ’11, Lauren Huyett ’11, Andrew Lai ’11, Zainab Nandawula ’11, and Glen Tennyson ’11.

They used statistical methods and analysis experiments to explore the behavior of current and alternative production strategies. This information was then used to provide suggestions on how to immediately improve cycle time and to increase throughput, while also suggesting longer-term strategies for improved process control and manufacturing methods.

David Lauritano ’11 worked on the microfueler project with Steve McClain ’12, Melissa Gordon ’11, Vince Kuperavage ’11, and Tafadzwa Munezvenyu ’11.

“We worked on developing and designing a portable apparatus that could produce fuel-grade ethanol for consumers and could be run out of their garage,” says Lauritano. “We ran distillation and fermentation experiments to help contribute to our final proposed design.”

Lauritano’s work on this commercially relevant project will help him with his new position in the project services group at ExxonMobil. “Any research on alternative energy is beneficial for the students involved and for the progress of alternative fuels. I also think working on a large semester project, like the microfueler, will help me approach projects at ExxonMobil. I learned how to work with a large group of people on one team.”

Other students who worked on the gas-to-liquids manufacturing facility project were Bryan Ertz ’11, Kathryn Friedman ’11, Jessica Swanson ’11, Kristin Garganio ’11, Anuoluwatomiwa Osunkoya ’11, Spencer Philpot ’11, Gregory Mandile ’11, Eeshan Sridhar ’11, Robert Lovelett ’11, Katie Wyttenbach ’11, Christopher Konen ’11, Andreas Kustas ’11, Ian Owens ’11, Eric Gratz ’11, Alexandra Smith ’11, and Jonathon Quodomine ’11.

1 Comment

Comments are closed.