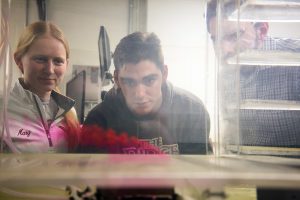

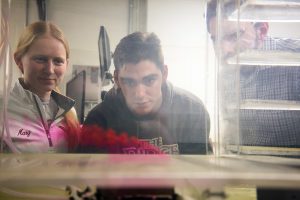

In a room on the bottom floor of Acopian Engineering Center, students cluster in the slim space around what looks like a mammoth fish tank draped in electronics.

Sometimes, they turn the lights out and fire lasers into the water. Often, they inject dyed liquid into a hose attached to the tank, turn on a motor and study how the smoky tendrils move over an object.

Sometimes, they turn the lights out and fire lasers into the water. Often, they inject dyed liquid into a hose attached to the tank, turn on a motor and study how the smoky tendrils move over an object.

What they learn is somewhat open ended. How does air hot enough to melt steel flow through a jet engine? How do weather patterns ripple around an island in the Pacific? How does air turbulence buffer a jetliner?

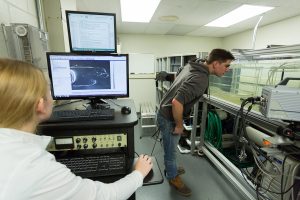

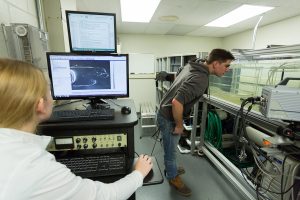

Dan Sabatino, associate professor of mechanical engineering, designed his own fluid mechanics channel and has even shared his design with other engineering schools. Constructed by Sabatino and a group of students a few years ago, the 1,400-gallon tank allows budding engineers to study flow phenomena like turbulence in a controlled environment.

It cost about $30,000 to build. It forms an L shape about 18 ½ feet long and 5 ¼ feet high. With all the equipment in place to create the flow test area, students have a space of about 2 ½ feet by 11 feet to test the flow dynamics on just about anything.

Sexy? Maybe not from a fundraising standpoint. The tank’s users aren’t guaranteed the creation of a better mousetrap every time. But channel research sheds light on unseen worlds and can poke holes in theories or help researchers develop new ones.

Sexy? Maybe not from a fundraising standpoint. The tank’s users aren’t guaranteed the creation of a better mousetrap every time. But channel research sheds light on unseen worlds and can poke holes in theories or help researchers develop new ones.

“This is very fundamental,” Sabatino says.

He used water channel research years before coming to Lafayette, but during a near decade stint at United Technologies, he hadn’t had the chance to do this kind of fundamental research.

“I had thought since I was out of the game for 10 years, I’d missed the boat,” Sabatino says. But he discovered little about the technology had changed.

Essentially, Sabatino spent two years building a wind tunnel with water in it with his students and EXCEL scholars, which now total more than 20.

It works for the study of fluid flow dynamics. For example, Lafayette students have used the tank to examine how fuel injection works on a combustion engine.

It works for the study of fluid flow dynamics. For example, Lafayette students have used the tank to examine how fuel injection works on a combustion engine.

The flow of water and air are similar, Sabatino says, but water gives the research advantage of slowness. Using dye and cameras, students can examine turbulence on a simulated aircraft wing.

“It looks like a mess,” Sabatino says. But within the mess, patterns can be discerned. Turbulence looks like a smoke ring with long tentacles that drag upon a surface.

Studying the patterns can lead to improvements in aerodynamics – a better, sleeker, and safer winged vehicle.

Or it might simply help tomorrow’s engineers understand how air and water flow works.

Sometimes, they turn the lights out and fire lasers into the water. Often, they inject dyed liquid into a hose attached to the tank, turn on a motor and study how the smoky tendrils move over an object.

Sometimes, they turn the lights out and fire lasers into the water. Often, they inject dyed liquid into a hose attached to the tank, turn on a motor and study how the smoky tendrils move over an object. Sexy? Maybe not from a fundraising standpoint. The tank’s users aren’t guaranteed the creation of a better mousetrap every time. But channel research sheds light on unseen worlds and can poke holes in theories or help researchers develop new ones.

Sexy? Maybe not from a fundraising standpoint. The tank’s users aren’t guaranteed the creation of a better mousetrap every time. But channel research sheds light on unseen worlds and can poke holes in theories or help researchers develop new ones. It works for the study of fluid flow dynamics. For example, Lafayette students have used the tank to examine how fuel injection works on a combustion engine.

It works for the study of fluid flow dynamics. For example, Lafayette students have used the tank to examine how fuel injection works on a combustion engine.