John Delfausse ’69 changed the cosmetics industry game by creating sustainable product packaging for Aveda

By Stella Katsipoutis-Varkanis

In the cosmetics industry, appearance is everything—and not just in terms of how the products make you look. Makeup, skin care, and hair care aisles in stores everywhere are bejeweled with one visually striking product after another, from shiny mascara tubes to candy-colored shampoo bottles. These eye-catching packages—designed to maximize display impact and appeal to consumers’ senses—are traditionally created with unrecyclable materials that are unsustainably sourced.

Now more than ever, however, cosmetic companies are using innovative methods to package and effectively market their products to buyers—without sacrificing the environment. And John Delfausse ’69 is one of the key industry players who helped them get there.

From 1993 to 2011, Delfausse—who received a bachelor of science in mechanical engineering from Lafayette—dedicated his career to implementing more sustainable practices at New York-based Estée Lauder Companies, serving in roles such as vice president of global package development and chief environmental officer.

Under his leadership, Estée Lauder-owned brand Aveda received multiple accolades for its green packaging, including the HBA 2003 International Package Design Award, DuPont Award for Packaging Innovation, and Greener Packaging Award, among others. A founding and executive committee member of the Sustainable Packaging Coalition, Delfausse was also named one of Packaging Strategies’ Most Influential in Packaging in 2008. Now retired, Delfausse continues to offer support to companies looking to enter the sustainable packaging arena.

In celebration of Earth Day, April 22, we sat down with Delfausse to talk about his many forward-thinking contributions to the industry—and his thoughts on the state of sustainability today.

What led you to your sustainable packaging career?

I majored in mechanical engineering at Lafayette, which gave me the foundation of investigating, researching, and solving problems. But when I got out of the Navy after the Vietnam War, there weren’t too many jobs in engineering. I ended up finding a job in cosmetic manufacturing. I kind of stumbled upon it.

I worked for a bunch of different companies—Coty, Avon, Elizabeth Arden, Estée Lauder. [My sustainable packaging career] came about because I took responsibility through the packaging of the Aveda brand for Estée Lauder. Aveda was a strong influence in helping me make some tough decisions in our packaging and getting it right.

I tend to be very creative, and maybe it’s just something engineers like to do—solve problems and keep it simple. I got into a situation where not only did I get to develop packages, but do something good for humanity and the Earth. And I could teach people new methods of development. It was very exciting to me, and it was a thrill to see people pick up on it and put it into action.

How do you define the term “sustainable packaging”?

The most important thing to me is that [a product] is beneficial, safe, and healthy for individuals and communities throughout its life cycle. The concept of sustainable packaging follows the cradle-to-cradle principle. The concept is it’s beneficial and healthy, and meets marketing criteria for performance and cost. You don’t sacrifice your performance, and you try to be as cost-effective as you can.

Then you get into the real environmental issues. Is it sourced, manufactured, transported, and recycled using renewable energy? It’s very important that you’re not, in your manufacturing process, being detrimental to the environment. Does it optimize the use of renewable or recycled source materials? If you’re building a package, do it with something that’s a renewable resource—such as paper or pulp—or a recycled material resource—like polyethylene or high-density polyethylene. Is it manufactured using clean production technology and best practices? You don’t want to use materials that could potentially be dangerous to the community or individuals. Is it physically designed to optimize materials and energy? You want to build a package so that it can use a minimum amount of material and energy in order to serve its purpose.

I would say you can’t do all these things. But if you’re doing something along the way on any one of these benchmarks, you’ll eventually be better on sustainability.

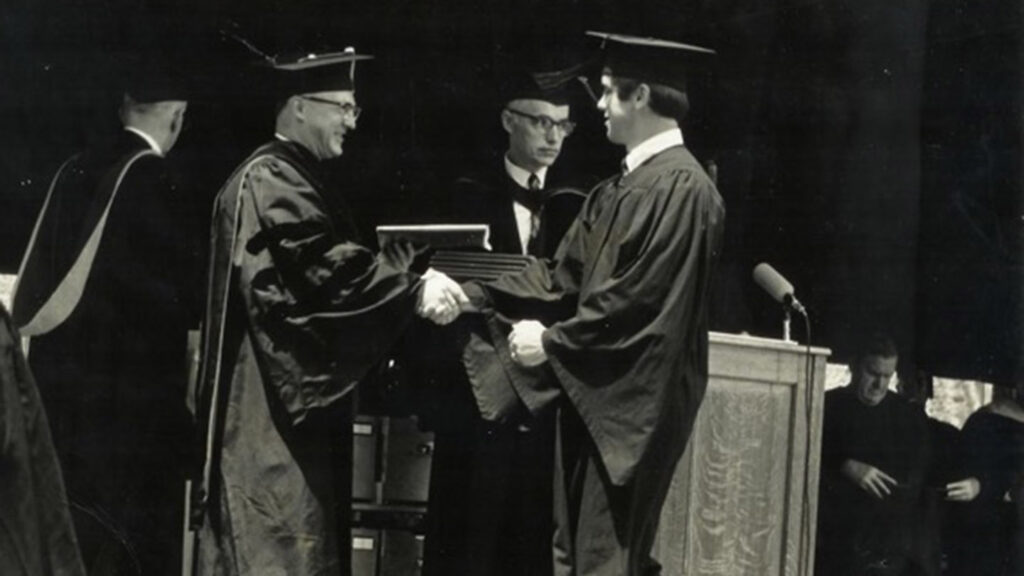

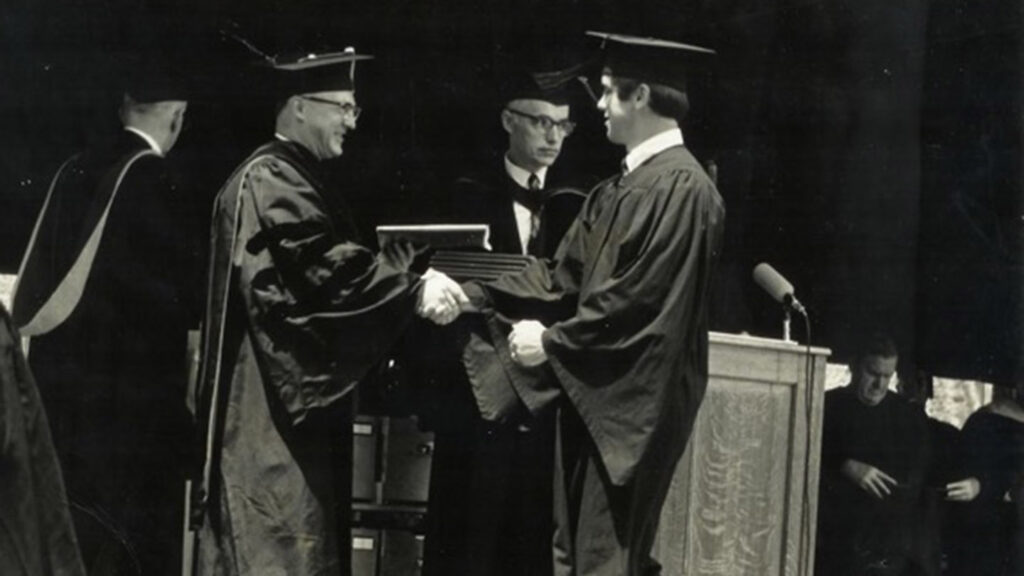

Delfausse receiving his Lafayette diploma in 1969.

What was your job like at Estée Lauder?

Estée Lauder is a big cosmetics company, and we had different brands. We bought a company called Aveda, and Aveda was very much into sustainability. I took over the responsibility for their packaging. I knew very little about sustainable packaging at that time, but I got very much into it very quickly.

When we first started with Aveda, basically what we did was build our packaging with recycled materials, and also made sure that there was a way our customers could return or recycle our packaging. If people couldn’t do that, we didn’t want to make it otherwise. We also tried to make sure that all the manufacturing of our products used renewable energy. I was able to take what we were doing in Aveda and bring it to the rest of the Estée Lauder Companies. The acceptance within the corporation was just incredible. I think Estée Lauder was an unusual kind of company because if you had a passion for something, they let you run with it.

I also went to talk to different companies and universities, teaching the basics of sustainability and what a difference it could make in their work. It was fun for me.

What were some of the biggest challenges you faced there?

I don’t call them challenges as much as opportunities. One of the things that our president wanted to do at Aveda was to simply make things at the highest level of recycled content we could. Our plastic bottles at the time I got there were using 10 or 15 percent recycled high-density polyethylene, and the goal was to get to 100 percent.

There are certain challenges to getting 100 percent recycled material into a personal care product. It took a number of years. We had to find resources for the high-density polyethylene, and the cleanest resource we could find was recycled milk bottles. There were two different companies we looked at, and we picked one we thought was the best at the time, and we went up from 15 to 50 percent recycled material. We did a lot of testing to make sure it wasn’t negatively influencing the performance of the package or the purity of the product.

Then they said can we do the same thing with tubes? The tubes were zero percent recycled material, and we got up to 45 percent in our tubes. But we couldn’t get any higher than that. So, we started talking about what we had to do to get beyond that. It took a couple more years, and we eventually got up to 85 percent. And then we said how do we get the last 15 percent? Well, the best way to do that was to use renewable source materials. And it was the development of polyethylene that was actually manufactured from corn. So, we had a renewable material—corn and cornstarch—which can then be manufactured into a polymer, which is renewable polyethylene. We mixed the recycled material with the renewable material, and we got up to a point where we got to 100 percent between renewable and recyclable materials.

We were able to teach the rest of the packaging group at Estée Lauder how to become more sustainable, and we started to keep track of what each brand was doing and benchmarking their progress.

In your opinion, what do other companies need to be more aware of in terms of sustainable packaging?

I think if companies want to be able to advertise themselves, they have to talk about what they’re doing on the level of sustainability. Packaging is just part of that. I always felt if we could do it in the cosmetics industry, which has very high and strict standards for packaging from a standpoint of quality and usefulness, you could do it in any industry.

My goal always was to build the sustainability in up front. It’s kind of hard to take existing items and make them more sustainable. But if you’re building something new, you can start from scratch probably at no additional cost—and build as much a quality of a package as you would if you didn’t even consider sustainability.

How did the Sustainable Packaging Coalition come about, and what were your goals there?

At one point I got together with some people in the industry, and they said there was going to be a meeting in Charlottesville, Va., and we formed what is called the Sustainable Packaging Coalition. We quickly grew to hundreds of companies that are all concerned about doing the right thing in packaging.

The coalition has all the major players in there—PepsiCo, and Coca-Cola, Microsoft. It was exciting for me because I met a lot of good people outside of the cosmetics packaging arena and worked with the industry throughout the United States.

We created a labeling concept called “How2Recycle.” So, you have a cereal box, and you have the plastic bag inside, which contains the product. The box has a little symbol on it that says you can recycle the box with paper, and the plastic bag inside can be recycled at Store Drop-Off. I’m seeing that on more and more packaging, which means more corporations started to take that as a responsibility.

What’s one thing you would like to make the world aware of this Earth Day?

One of the things that’s always bothered me is that recycling has not been doing so well lately. You would think that the average PET soda bottles are being recycled at a very high rate. The rate of recycling soda bottles is under 30 percent. I think it’s got so much further that it has to go.

People say it’s hard enough to get people to recycle, and people won’t separate stuff at home. Well, if you can go to a grocery store and pick out what you want from hundreds of thousands of different items, I think you can separate it into glass and paper and plastic. Kids have to grow up with that kind of thing in mind. I think that’s something that, as an industry and as a country, we need to do a better job of.

Do you have any final thoughts you’d like to leave Lafayette students with?

I had a long career in packaging, and it didn’t really have anything to do with mechanical engineering. You never know what career you’re going to get into. I took a job and—because of my engineering and manufacturing background, and because it was in cosmetics—it brought me to a worthwhile and rewarding career. I didn’t start my sustainable packaging career until the last 18 years of my career. So even when you start out in something you’re not absolutely passionate about, you might find out later on that you’re in the perfect job to get you to doing something you’re very passionate about.

3 Comments

Very interesting article. As someone who spent his career working for state environmental agencies and, after retirement, working part-time for a small private environmental organization, I certainly can appreciate John’s drive and ingenuity for doing the right thing when it comes to packaging in a sustainable fashion.

Roy Miller, Class of 1968

Nice to read an article about a fraternity brother and classmate.

Great accomplishment and an important issue for our future.

And John looks great 50 plus years later!

Great news about a fellow Leopard of 1969

Comments are closed.