Student-professor partnership makes the most of remote learning experience to boost robotics research

By Bryan Hay

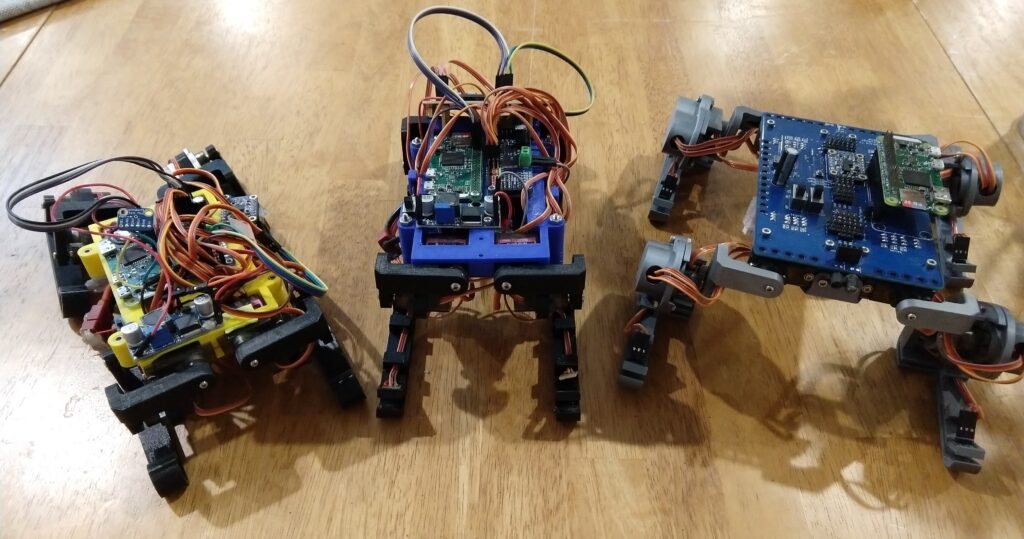

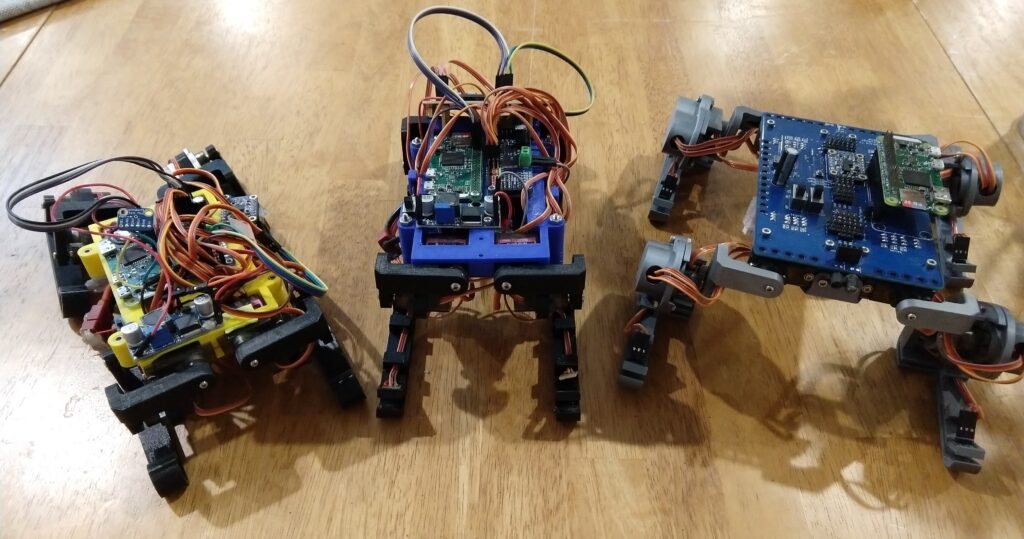

A well-coordinated student-professor collaboration that overcame the obstacles of remote learning has brought to life quadruped robot triplets.

Gabrielle Conard ’21 (mechanical engineering) began working with Alex Brown, assistant professor of mechanical engineering, during spring semester and into the summer on a low-cost quadruped robot design.

“She would design parts, and I would print them or solder them at home as appropriate, and ship them to her,” Brown says. “As part of her EXCEL research over the summer, we used this remote collaboration model as she completely redesigned our low-cost robot platform to use a structural printed circuit board chassis with onboard 8-bit microcontroller, a connection for a Raspberry Pi, a credit-card sized computer, plus integrated servo control and force sensing circuitry.”

Together, they created three iterations of the quadruped robot, one designed by Brown, the second designed by Conard during spring semester, and a third developed over the summer as part of the EXCEL project.

IEEE Spectrum featured Conard’s work in a story about how researchers, academics, engineers, and students have adapted to lab, classroom, and business closures by taking their robotic projects home with them.

Taking a break from her busy academic schedule, Conard described her work and how her collaboration with her professor led to a successful project.

Clearly, the two of you developed a very efficient system, despite the challenges of working remotely. Can you describe that experience and how your teamwork helped overcome the limitations of the closed campus?

One of the major challenges about being sent home for the spring and summer was not having access to vital tools, such as 3D printers, to manufacture prototypes of the robot’s components. We eventually developed a system in which I would design a 3D printed part or an electrical circuit in Fusion 360 (a CAD software), and Prof. Brown would make it on his printer and give me feedback on how to improve it. Once I had developed the robot’s components and we were satisfied with how each of them turned out, he would ship the parts to me. It was always exciting to get that package in the mail!

While it was initially frustrating not being able to simply run down to the 3D printer lab in Acopian and see how my new part turned out, the process certainly strengthened my design skills. Since I couldn’t print things at my leisure (and Prof. Brown has a life outside of our project), I had to put much more thought ahead of time into the design, such as ensuring that different parts aligned properly, to limit the number of iterations.

What was your greatest challenge working remotely and without regular human interaction?

While I am a more introverted person and coped fairly well during quarantine, I really missed seeing the Lafayette community on a regular basis. I realized just how much I appreciated bumping into a friend or professor around campus or those rushed conversations with classmates in the three minutes before a class started. It was also difficult to collaborate on homework since we could not see each other’s papers to compare approaches to a problem.

However, I am very grateful that my friends and I were able to stay connected from nearly the first week we were sent home, whether that was eating lunch together over Zoom or attempting to work on a problem set together, even if that meant holding up my scribbled answer to the camera. Those meetings prevented me from feeling disconnected from the community.

What’s the goal of your independent study robot project, and what is meant by “incorporating active compliance in a low-cost” quadruped robot?

While much work has been done on larger-scale robots, such as Boston Dynamics’ Spot or the MIT Cheetah, not much progress has been made in developing smaller and cheaper quadruped robots that can be used for research. That means that if you want to perform research on quadrupeds, such as investigating gait patterns or developing navigation algorithms, you need a rather large budget to get a robot platform to work on, as well as experience in some complex computing.

Our goal during the independent study, and now for my thesis, is to make this field more accessible by developing a low-cost research-grade quadruped robot that can be used as an inexpensive platform for research or even for robotics education.

One of the features that we wanted to include was active compliance. Active compliance is a way of using software to sense the force applied to each limb and create ‘soft joints.’ For example, if you were to jump, when you land, you would bend your knees to absorb the impact detected by your feet. Keeping your legs stiff could cause injury to your knees or back.

Similarly, we wanted to develop that ability in our robot to protect it from falls and unexpected obstacles. The benefit of using software to do this, rather than a physical spring, is that we can adjust the stiffness of the joints depending on the application.

While this has been done with more expensive robots, the motors used to do this are far outside of our budget. As a result, we developed a different method using force sensors that we designed and RC servos. Now that we have accomplished this, we plan to refine the robot’s ability to respond to obstacles to navigate rough terrain.

Are you still working on the project, or is your independent study finished?

I continued working on it as an EXCEL Research Scholar over the summer, during which time I focused mostly on addressing a number of flaws in the original robot design (both mechanical and electrical) and developing a new prototype. This set me up well to pursue a thesis this year, in which we plan to implement new features such as walking over rough terrain, avoiding obstacles, and climbing a stair.

What is the robot capable of doing?

Currently, the robot can respond compliantly to force being applied to the chassis by bending its legs to absorb the weight. In addition, it can walk untethered (meaning that it doesn’t need to be plugged into a computer or power source), albeit somewhat shakily. It is so close to walking smoothly; there are a few aspects of the software that I need to adjust to achieve that.

What are your key takeaways from the project?

I’ve been doing research with Prof. Brown for over a year now (during the summer of 2019 working on the Lafayette OpenDog project and during the spring and summer of 2020 working on the low-cost robot), and I have been amazed at the amount of confidence I have gained during that time.

Despite the fact that I had done well in classes and had some hand skills, I did not feel at all confident about developing my own designs or experiments. Having a space to learn, try things out, make mistakes, and learn some more was really helpful for me. While I still get unsure of myself sometimes, I can say that I am much more confident in developing my own ideas than the somewhat-intimidated sophomore that walked into LeopardWorks for the first day of research last summer.

What have you enjoyed most about the experience?

Hands down, my favorite aspect about doing research is the amount that I get to learn in the process! Throughout this project, I’ve had to sharpen my mechanical design skills, learn how to design a custom circuit board, develop coding skills, and read a wide array of technical papers spanning the fields of robotics, computer science, biology, and neuroscience.

While developing this robot, I have had to draw from introductory engineering courses such as Dynamics and Strength of Materials as well as advanced courses such as Instrumentation and Control Systems. In addition to learning new skills and concepts, I have also enjoyed seeing how the things I am learning in my classes can directly apply to this project.

Seeing how the concepts I practiced on weekly problem sets can be used for a ‘real’ project has been incredibly cool!

What are your plans after Lafayette?

I am planning on going to graduate school to pursue a research-based master’s degree in robotics or some related subject, but I am considering taking a gap year before graduate school to get some experience in industry. Some fields that use robotics that particularly excite me are space exploration, assistive technology, and theater and stagecraft.