Chemical engineering faculty and Learning and Research Technologies staff collaborate on identifying virtual streaming technology

By Bryan Hay

Lafayette chemical engineering students in China are participating in virtual streaming labs, through the combined resourcefulness of faculty and Learning and Research Technologies (LRT) staff who supplied cameras and microphones to bring the learning experience closer to home.

“One of the hallmarks of Lafayette’s chemical engineering program is the hands-on experience of a three-course experiential laboratory sequence,” says Lauren Anderson, department head and associate professor of chemical and biomolecular engineering. “Over the course of three semesters from fall of junior year to fall of senior year, students progress from bench-scale measurements to operating pilot-scale industrial equipment.”

Due to the COVID-19 shift to remote learning in the second half of the semester last spring and a fully remote fall semester, students in the Class of 2021 were deprived of this hands-on experience, a critical part of their preparation for careers in industry.

Kristen Swaun ’21 (forefront) and Ryan Moerder ’21, holding camera, assist in hybrid chemical engineering lab

Chemical engineering faculty decided to split the senior fall course, CHE 412 Integrated Chemical Engineering, into two half-credit courses, CHE 417 ICE I and CHE 418 ICE II, to preserve the ability of students to operate the pilot-scale equipment.

“In fall 2020, students remotely learned how to conduct a hazard and operability study, an important skill in process safety, and investigated a virtual reactor experiment using data sets and troubleshooting exercises,” Anderson says.

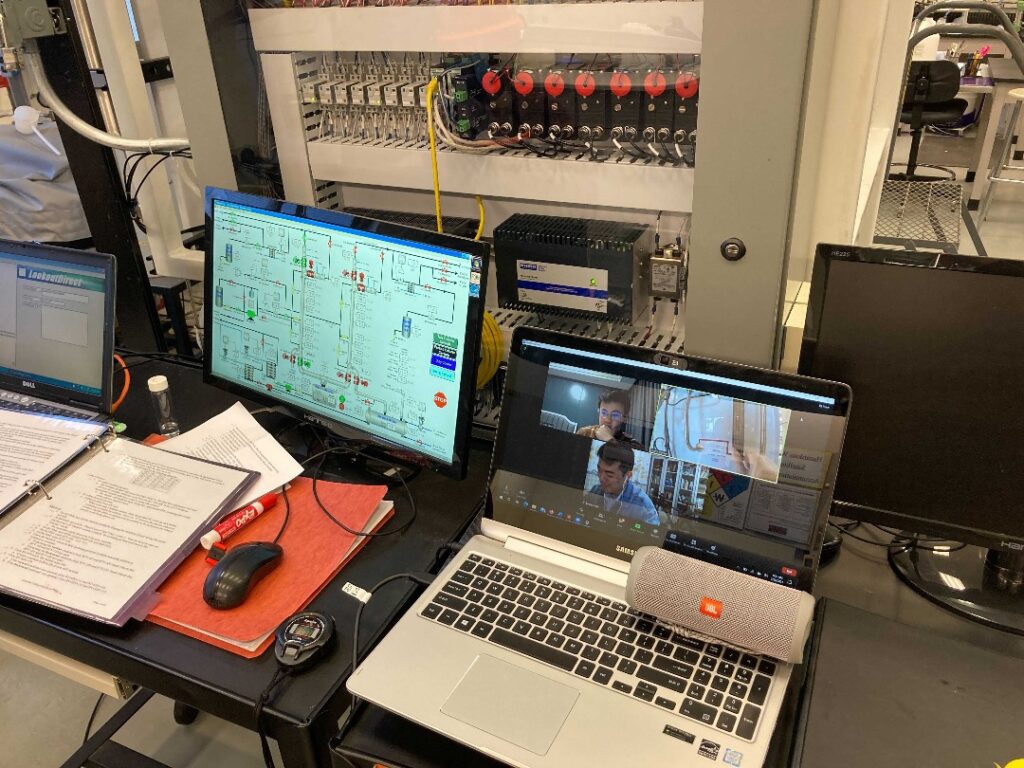

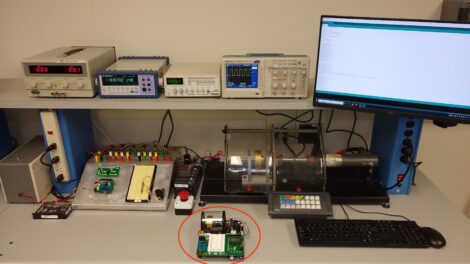

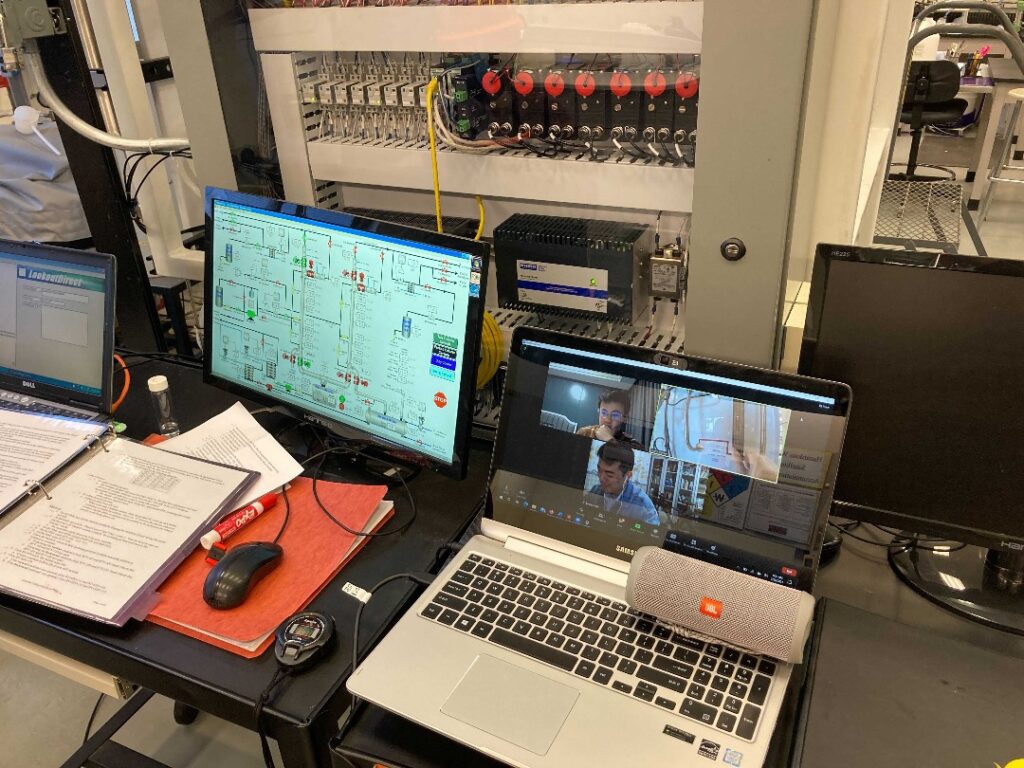

The equipment in the lab allows students to study concepts of heat and mass transfer, while working with a shell and tube heat exchanger, a gas absorber, a continuous distillation column, and a reverse osmosis membrane.

“Using a packed bed gas absorber, students work to remove acetone from a contaminated waste airstream,” Anderson explains. “The packed column with an electric reboiler is used to teach the principles of continuous distillation as students try to separate ethanol from an ethanol/water feed stream. Lastly, students study the effect of pressure on separating salt from brackish water using reverse osmosis as the separation technique.”

Currently, the majority of students are back in person in the laboratory, gaining the experience of running the equipment.

“However, four of our students, Ziyang Guan ’21, Shiqing Ma ’21, Leon Yang ’21, and Alex Qian ’22, are completing their degrees remotely from China,” she says. “In an effort to give them the best possible ‘live’ experiences, I consulted our amazing experts in LRT to equip the labs with the right technology for virtual streaming during the lab period.”

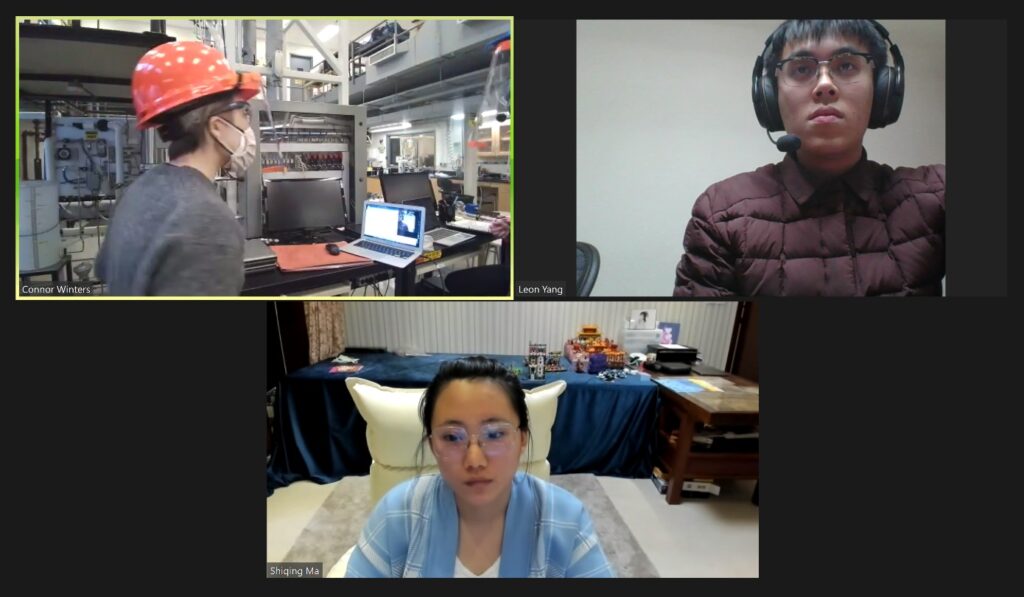

Alex Qian ’22 (upper Zoom box) and Ziyang Guan ’21 participate in hybrid chemical engineering lab

Yang, who lives in Shanghai, is thankful for the efforts that help bring the lab experience a little closer.

“Through the extensive efforts by the professors and staff, we are able to recover a great deal of our experience that would have been lost to the current challenges,” he says. “Overall, I believe that I am able to keep up with my peers, despite being halfway across planet Earth. As Class of 2021 chemical engineers, we are arguably some of the people struck the hardest by the COVID-19 shutdowns.

“Beginning in our spring semester junior year, we were not able to continue our in-person learning experience. Being at home in China meant that we faced international travel restrictions that prevented our returning to campus even in our senior spring semester,” Yang says. “This meant that we missed out on nearly half of our in-class labs, which are critical. However, the professors courteously arranged ways for us to engage with our peers as much as possible.”

Qian, from Hangzhou, Zhejiang province, in southeastern China, says the video equipment allowed him and his lab mates to view the laboratory from different angles.

“The audio was crystal clear, and the views shown on the screen were high resolution,” he says. “With the help of this system, we interacted more with our in-person lab partners. Prior to that time, we could only see a pretty vague contour of the equipment and couldn’t tell what our partners were doing.”

Their engagement has been further maximized through two strategies, Yang notes.

“Firstly, we sharpened our knowledge of the experiments as well as our analysis skills by designing actual experimental procedures and performing real data analysis,” he says. “By reviewing resources from previous years’ students, we got to know every detail of the experiment in order to draft a successful procedure.

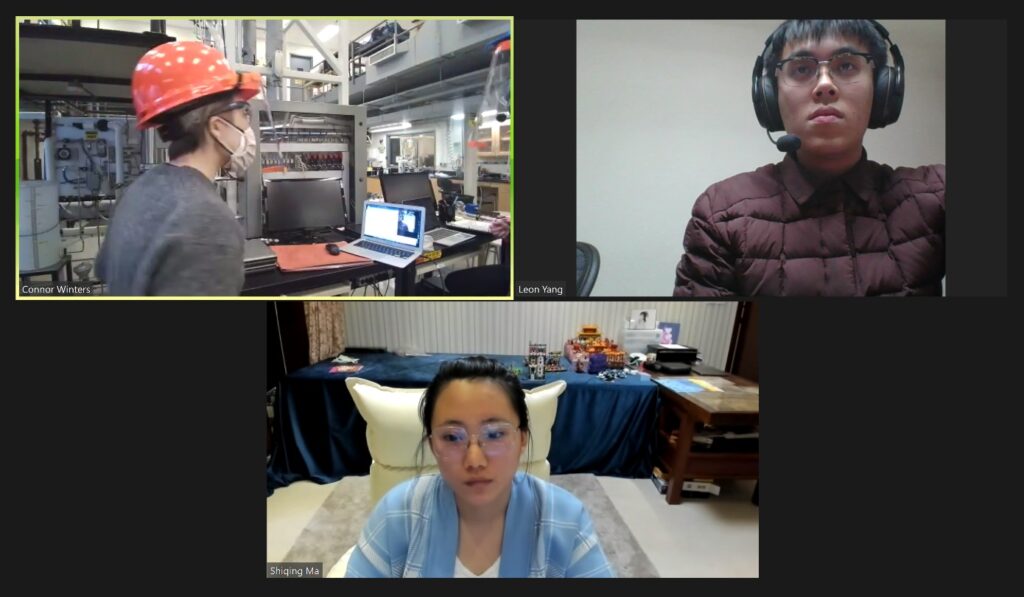

Prof. Lauren Anderson (upper left) helps coordinate lab with Shiqing Ma ’21 (bottom) and Leon Yang ’21

“Then, using real data collected from prior groups, we were tasked with carrying out analysis. Using data was an excellent learning experience as we faced deviations and problematic information that honed our critical thinking abilities to understand and solve.”

Video calls to peers working in the lab also helped. “Despite a challenging start, we quickly worked out the optimal configuration with help from the IT department so we were able to communicate with our peers flawlessly while keeping up with our peers’ work,” Yang says.

Some refinements still need to be worked out, Anderson says, including improvements to audio quality and perhaps rigging up a GoPro-type camera that can be attached to hard hats and integrated with Zoom.

“It’s a continuous process of improvement, and I’d like to thank our experts in Learning and Research Technologies, especially E.J. Hudock for his help setting all this up and iterating over time,” she says.

Considering the additional challenges of conducting hybrid lab work in two different global time zones, Anderson scheduled with empathy.

“The lab was initially scheduled to be 1:10-4 p.m. EDT, so once I realized four students would still be in China, I moved it to 8 a.m.,” she says. “So although it’s still a late night for them, it is much better. The students seem to prefer to stay up late than get up early, so I think the 8 a.m. start has more of an effect on the in-person students.”